Image

Recover waste heat to cut emissions and boost energy efficiency

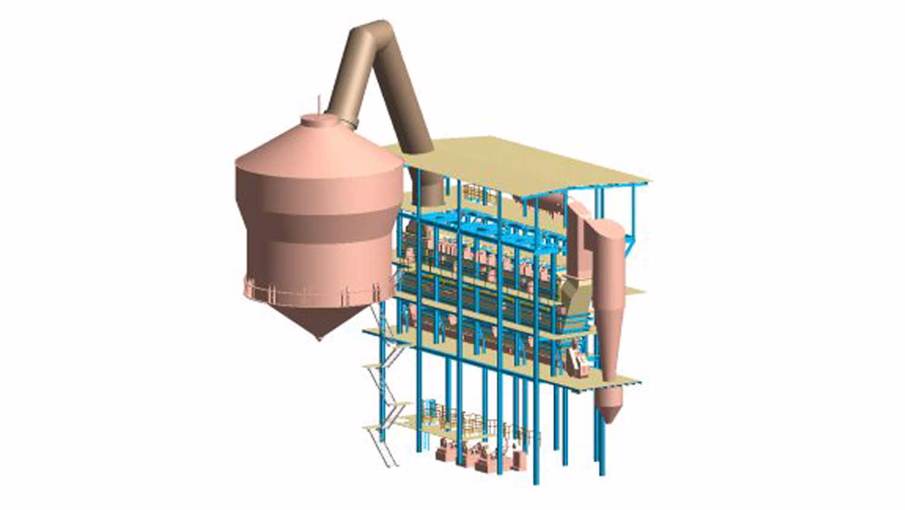

Recovering waste heat is a critical challenge for industries aiming to improve efficiency and reduce emissions. Sumitomo SHI FW’s Waste Heat Boilers provide a proven solution by capturing energy from hot process gases in metallurgical operations, turning it into valuable steam for power generation and heating.

With a robust design and seamless integration into existing processes, our WHBs help reduce fuel consumption and carbon emissions while ensuring uninterrupted operations.

Tabs

Step 1: Capturing Heat from Hot Process Gases

Hot gases produced during non-ferrous pyrometallurgical processes, like smelting or roasting, flow into the Waste Heat Boiler. The WHB captures this heat, preventing energy loss and preparing it for reuse in the plant’s operations.

Step 2: Generating Steam for Industrial Use

The captured heat is transferred to water within the WHB, producing steam. This steam powers various processes, such as electricity generation, drying, or heating, improving the plant’s energy efficiency and bottom line.

Step 3: Supporting Emissions Control

As the gases cool within the WHB, the system enables additional steps, like dust removal and gas cleaning. This includes recovering sulfur for use in acid plants, further reducing environmental impact.

Reliable Performance in Harsh Conditions

These boilers are built to withstand corrosive gases, molten ash, and high temperatures. Thick-walled, small-diameter boiler tubes add extra durability, ensuring reliable performance over time.

Optimized Efficiency with Custom Design

Our technology can be installed in newly built plants or retrofitted into existing ones. This flexibility allows it to enhance overall plant efficiency.

Effective Gas Cleaning

Improved gas cleaning processes, including sulphur recovery, facilitate dust removal and significantly reduce harmful emissions.

Patented Boiler Cleaning

Our patented spring hammer rapping system prevents dust and debris buildup on boiler tubes, ensuring steady performance and minimizing maintenance.

Enhanced Energy Utilization

Our WHB technology allows industries to make the most of their energy resources by turning waste heat into useful energy, helping to lower fuel consumption and reduce operational costs.

Reduced Carbon Emissions

By capturing waste heat, WHBs contribute to a significant reduction in carbon emissions, supporting sustainability targets and compliance with environmental regulations.

Reliable and Low-Maintenance Operation

With a durable design and an efficient cleaning system, our WHBs minimize downtime and maintenance. Over 100 installations worldwide attest to their dependable performance and energy efficiency.